Utilize Pyrolysis Plant to Efficient Waste Management

The global surge in solid and hazardous waste generation has intensified the need for efficient and sustainable treatment technologies. Among emerging solutions, the pyrolysis plant has demonstrated superior capability in transforming waste into valuable secondary resources while minimizing environmental impact. By converting organic materials into fuel oil, syngas, and char, pyrolysis serves as a cornerstone in the circular economy—linking waste recovery, energy production, and carbon reduction in a unified process.

Converting Waste into Energy Resources

A plastic pyrolysis plant converts non-recyclable polymer waste into usable hydrocarbons through controlled thermal decomposition. This closed-system process operates in the absence of oxygen, ensuring that plastics are not incinerated but thermally cracked into liquid fuel and combustible gases. The generated oil can substitute conventional petroleum-based fuels in industrial furnaces or power generators, while the syngas supports self-sustaining plant operation by providing internal heating energy. This dual recovery mechanism drastically reduces dependence on fossil resources and limits carbon emissions associated with plastic disposal.

The same principle applies to rubber and tire waste. A tyre pyrolysis plant processes discarded automobile tires into pyrolytic oil, recovered carbon black, and steel wire. Each by-product retains significant economic value. Recovered carbon black is repurposed in manufacturing rubber compounds or pigment materials, contributing to material circularity. This technology directly alleviates the environmental burden posed by tire stockpiles, which are notoriously difficult to degrade under natural conditions.

Integration of Advanced Thermal Technologies

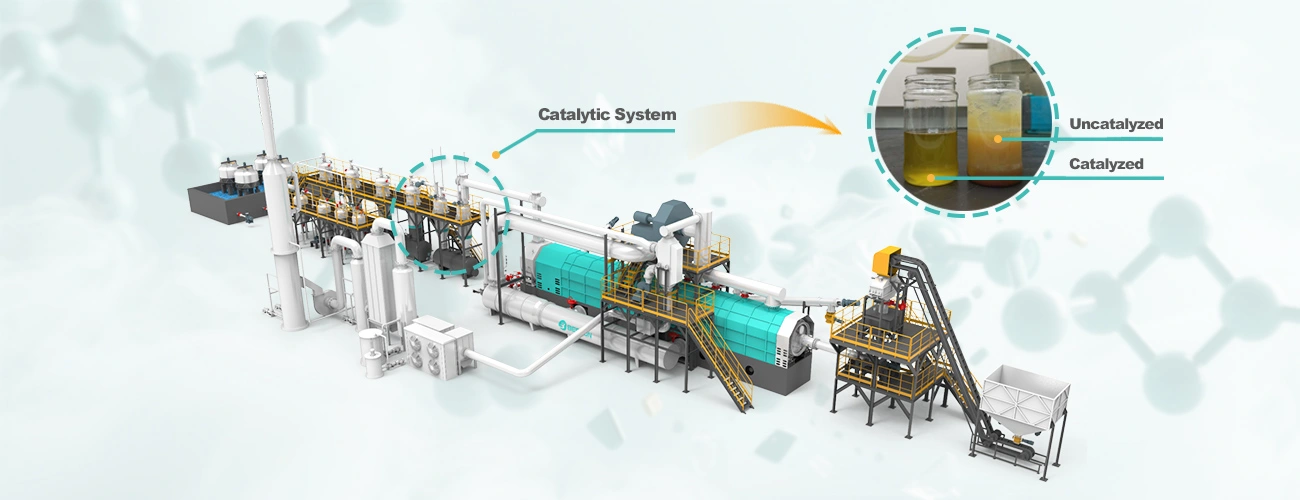

Modern pyrolysis facilities often incorporate auxiliary systems such as a thermal desorption unit for the treatment of oil-contaminated solids or sludge. This unit uses high-temperature volatilization to separate hydrocarbons from inert substrates, achieving efficient recovery while meeting environmental discharge regulations. When integrated with pyrolysis lines, thermal desorption technology ensures comprehensive waste management—addressing both solid and semi-solid residues within a single processing framework.

Such hybrid configurations enhance throughput capacity, reduce the need for external energy inputs, and optimize overall thermal efficiency. Process integration also simplifies emissions control, as treated gases can pass through unified purification systems including condensers, scrubbers, and activated carbon filters.

Economic Viability and Market Adaptation

Investment decisions in pyrolysis technology often depend on the pyrolysis machine price relative to production scale, energy recovery efficiency, and feedstock availability. While initial capital costs vary, operational payback is typically rapid due to high-value product yields and low disposal expenses. In developing markets, modular pyrolysis systems are particularly appealing because they can be deployed with minimal infrastructure and operated using local labor and resources.

The adaptability of pyrolysis plants to different waste streams—plastics, tires, biomass, or oil sludge—further enhances their market relevance. Policymakers and private investors increasingly view pyrolysis as a long-term solution that meets both waste reduction and renewable energy objectives.

Toward Sustainable Waste Valorization

The deployment of pyrolysis technology, like tyre pyrolysis plant, marks a pivotal advancement in the evolution of sustainable waste management. Beyond material recovery, it facilitates energy independence, lowers greenhouse gas emissions, and diverts massive quantities of waste from landfills. Integrated systems combining pyrolysis, gas purification, and desorption processes exemplify how industrial innovation can reconcile economic benefit with ecological responsibility.

As urbanization accelerates and environmental regulations tighten, the global transition toward resource-efficient waste treatment will continue to expand. The modern pyrolysis plant stands at the forefront of this transformation, providing a scientifically grounded and economically feasible pathway to convert persistent waste into renewable value streams.